Causes of Rust

There are a few main causes that lead to the formation of rust on metals like iron and steel. The primary cause is the presence of oxygen and moisture in the air. Iron readily reacts with oxygen in a chemical reaction called oxidation to form rust. Moisture also exacerbates the rusting process by allowing oxygen to more easily penetrate the metal surface. Another major cause of rusting is the presence of impurities in the metal itself that may accelerate corrosion. Chlorides from salt water or road salt are particularly corrosive impurities that can cause rapid rusting. The environment can also influence rust formation – areas with high humidity or marine settings near the ocean tend to see more severe rust problems.

Mechanical Rust Removal Methods

For light to moderate surface rust, simple mechanical methods can be effective for removal without using harsh chemicals. Wire brushing is a basic option that uses stiff metal bristles to scrub away loose rust flakes. This works well for accessible surfaces. Sanding with abrasive paper from coarse to fine grits is also a good method that gradually Rust Remover as you smooth the surface. For areas that are pitted with deep rust, using a drill attachment with a wire cup brush allows more aggressive scrubbing. These mechanical methods prepare the surface for further rust prevention options.

Chemical Rust Removers

When rust is more firmly attached or coating large areas, chemical rust removers provide a faster and thorough solution. There are a few main types of chemical rust removers to consider. Acid-based removers use acids like phosphoric or hydrochloric acid that chemically react with rust to dissolve it away. They work quickly but require protective equipment and neutralizing after use. Alkaline or caustic rust removers rely on strong bases like sodium hydroxide or potassium hydroxide that saponify and liquefy rust for removal. They also demand safe handling measures. More user-friendly options are citric acid-based and oxalic acid-based removers that act as mild acids capable of removing light to moderate rust without presenting severe hazards. Chemical removers come as gels or liquids to coat the rusted surface for a recommended reaction time before washing away. Always wear protective gloves and follow product instructions carefully with chemical-based rust removers.

Surface Preparation Methods for Rust Prevention

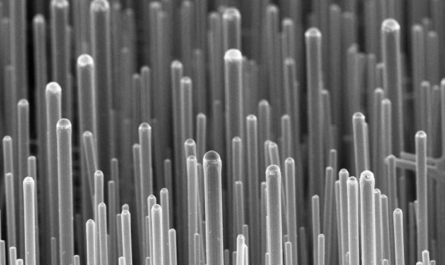

Once rust is removed, it’s important to properly prepare the underlying metal surface to prevent new rust from forming. Thoroughly cleaning and drying the surface is the first step. For steel, using a wire brush, solvent or abrasive paper can expose fresh unrusted metal. This allows proper application and adherence of subsequent protective coatings. Another key preparation method is sandblasting, which uses an air compressor to project an abrasive material like sand or grit to buff the surface and profile it for maximum coating adhesion. Surface treatments can also be applied as an additional protective barrier before topcoats. Examples are phosphating, which forms a chemical conversion coating of phosphate on steel surfaces, or primers that provide an initial layer of corrosion protection.

Protective Coatings for Rust Prevention

With a clean, dry and properly prepared surface, long-term rust prevention becomes possible through the application of protective coatings. Oil-based and water-based paints are common choices that form a physical barrier isolating the metal from the atmosphere. Paint options like alkyd, latex and acrylic formulations suit varied application needs. Epoxy paints or coatings offer superior protection against corrosion in demanding environments due to their excellent adhesion and chemical resistance qualities. For metal exposed to continuous moisture or submersion in water, marine-grade epoxy paint or two-part high-build epoxy primers provide industry-leading protection. Where painting restrictions exist, barrier rust preventative products like waxes, oils or rust convertors can be applied by solvent cleaning and allowing them to dry. These form non-porous barriers to keep rust-causing elements away. With proper coating selection and reapplication periodically as needed, rusting of treated surfaces can be very effectively controlled for many years.

Sealing and Covers for Enclosed Areas

Completely sealing off metal surfaces from air and moisture contact is another sure way to halt rusting in its tracks. For items stored long-term or installed in enclosed areas, proper sealing techniques become crucial rust prevention steps. Applying rust preventative petroleum jellies or using grease-impregnated barrier tapes helps lubricate and shield cut edges and joints that are vulnerable to corrosion. Corrosion-inhibiting spray-on sealants and rubberized undercoating sprays coat intricate locations for protective sealing. Plastic caps, plugs or end seals help close off open tubes, pipes or fixtures. Storing metal parts or equipment inside humidity-controlled sheds, containers or sealed bags with desiccant also denies rust the oxygen and moisture it needs to persist. In environments where complete sealing isn’t feasible, applying additional protective coatings as outlined above achieves reliable rust prevention. Combined, these sealing and coating methods eliminate rust worries for the long run.

About Author - Ravina Pandya

Ravina Pandya,a content writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemicals and materials, etc. With an MBA in E-commerce, she has expertise in SEO-optimized content that resonates with industry professionals. LinkedIn Profile