With growing concerns over air and water pollution, industries are under increasing pressure to reduce their emissions and effluents. One technology that has proven highly effective in achieving this goal is the scrubber system. Scrubbers help control air and water pollution by capturing contaminants before they are released into the environment. In this article, we will discuss the working of scrubber systems, their various types and applications.

Working of a scrubber system

A scrubber system works on the principle of contact absorption. It involves the direct contact of a polluted gas or liquid stream with another liquid stream or abrasive solids. This contact allows the transfer of some components from the gas or liquid to the scrubbing fluid or particles. The four key steps involved are:

– Contacting the polluted gas or liquid stream with the scrubbing medium inside the scrubber vessel. This can be a spray tower, packed tower or venturi scrubber.

– Absorption and capture of targeted pollutants like particulate matter, acid gases or heavy metals by the scrubbing liquid or solid particles. Common scrubbing mediums include water, alkaline solutions or slurries.

– Removal of the contaminated scrubbing medium from the scrubber vessel.

– Treatment and disposal or reuse of the scrubbing medium laden with captured pollutants. The pollutants can be separated, treated and disposed while the scrubbing medium may be regenerated and recycled.

Types of Scrubber System

There are different types of scrubbers designed to capture specific pollutants from gas or liquid streams:

Venturi Scrubbers

Venturi scrubbers use the Bernoulli’s principle to rapidly introduce and break up the polluted gas stream into small bubbles within the scrubbing slurry. They are effective at capturing particulates and some acid gases. Commonly used in power plant and waste incineration applications.

Packed Tower Scrubbers

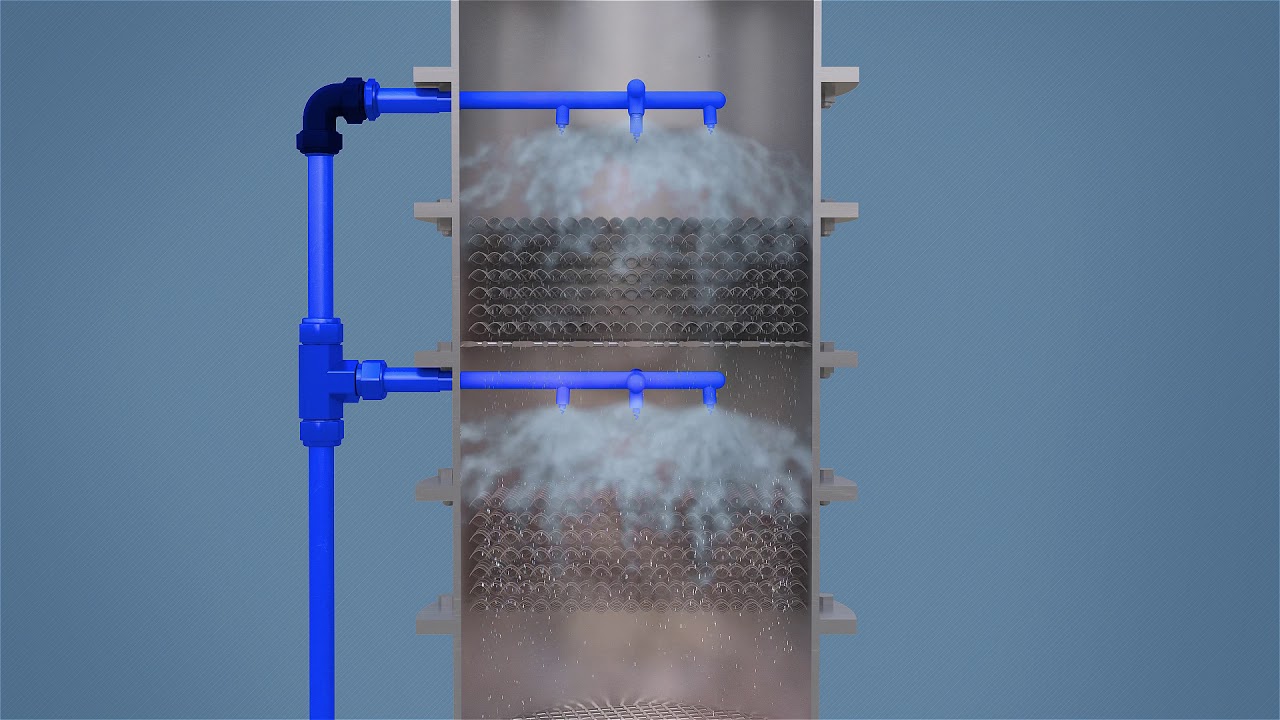

In packed towers, the polluted gas is brought into intimate contact with downward flowing liquid across structured or random packing material inside the tower. They have high removal efficiencies and are used for absorbing gases like SO2, HCl and other acid gases.

Spray Towers/Chamber Scrubbers

In spray towers, the gas stream is uniformly dispersed with scrubbing liquid sprayed through nozzles. The finely divided liquid provides large surface area for absorption. Used for flue gas desulfurization and particulate removal in chimneys.

Venturi Wet Scrubbers

Wet venturi scrubbers combine the venturi principle and direct contact of spray droplets to capture pollutants. Commonly used for removing dust, fumes and mists from industrial exhaust systems.

Applications of scrubber systems

With their high pollutant removal effectiveness, scrubbers find widespread applications across many industries:

Power Generation

Scrubbers are installed in coal-fired power plants to remove sulfur dioxide in flue gases through wet FGD systems. Dry sorbent injection systems use dry scrubbing for the same purpose.

Waste Incineration

Wet and dry scrubbing systems help municipal and industrial incinerators meet stringent emission norms for particulates, dioxins, furans and acid gases.

Pulp and Paper Industry

Wet scrubbers capture odorous gases, particulate matter and toxins emitted from pulp cooking, bleaching and paper making processes.

Surface Coating Operations

Scrubbers effectively control volatile organic compound emissions from spray painting, powder coating and surface preparation activities.

Metal Processing Industry

Wet scrubbing of emission from metal smelting, refining and surface treatment processes removes toxic metals, acids and particulates.

Advantages of scrubber systems

Scrubbers provide a viable solution to industries struggling to meet environmental regulations. Their key advantages include:

– High removal efficiencies of over 90% for most targeted pollutants.

– Versatility to capture different pollutant types like particulates, gaseous and vaporous emissions.

– Ability to treat high volumes of polluted gas streams.

– Minimize emissions to levels below regulatory discharge limits.

– Potential to recover valuable by-products from scrubbing processes.

– Long equipment lifespan with proper maintenance and monitoring.

Challenges and the way forward

While scrubbers are a proven pollution control technology, their deployment does pose some challenges. High capital and operating costs, complexity of multistage scrubbing circuits and potential chemical hazards are some hurdles. Advances in material science and process engineering can help address these issues. Wider adoption of dry scrubbing technologies and techniques like ultrasonic atomization hold promise to make scrubbers more efficient and cost-effective in the coming years. With the growing emphasis on sustainability, scrubber systems will continue playing a key role in enabling industries to operate responsibly while meeting environmental standards.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it