Market Overview:

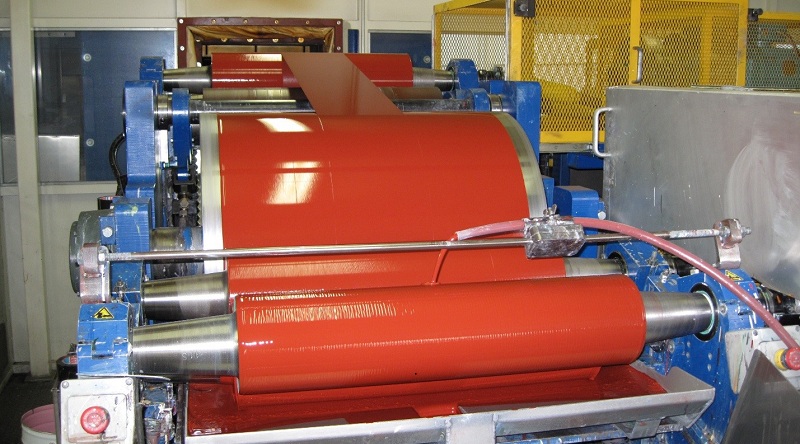

Coil coatings are used to protect and enhance the lifespan of metal surfaces, such as aluminum and steel coils, which are extensively utilized in various industries including construction, automotive, and appliances. These coatings provide corrosion resistance, durability, and aesthetic appeal to metal substrates. The increasing construction activities, rapid urbanization, and growing demand for sustainable and energy-efficient buildings are driving the demand for coil coatings.

Market Key Trends:

One key trend observed in the coil coatings market is the increasing adoption of eco-friendly and sustainable coil coating technologies. With growing environmental concerns and government regulations regarding VOC emissions, there is a rising demand for low-VOC or zero-VOC coil coatings. Manufacturers are focusing on developing water-based and powder coatings that have minimal environmental impact without compromising on performance.

For example, AkzoNobel, a key player in the coil coatings market, offers a sustainable coil coating system called CERAM-A-STAR 1050. This system is solvent-free, has low VOC emissions, and is energy-efficient. It provides superior weather resistance and durability, making it suitable for architectural applications.

Porter’s Analysis:

The threat of new entrants:

The coil coatings market has high entry barriers due to the requirement for significant capital investment and expertise in coating technologies. Established players already have strong distribution networks and customer relationships, making it difficult for new entrants to compete.

Bargaining power of buyers:

The coil coatings market is fragmented, with numerous suppliers offering a variety of products. Buyers have a moderate level of bargaining power as they can switch between suppliers based on price, quality, and service offerings.

Bargaining power of suppliers:

Coil coatings manufacturers rely on raw material suppliers, such as resins, pigments, and additives. These suppliers have a moderate level of bargaining power as they can influence the cost and availability of raw materials.

The threat of new substitutes:

‘There are no direct substitutes available for coil coatings in terms of protecting and enhancing the lifespan of metal substrates. However, alternative coating technologies, such as liquid coatings and anodizing, pose a potential threat to the coil coatings market.

Competitive rivalry:

The coil coatings market is highly competitive, with key players focusing on product innovation, partnerships, and acquisitions to gain a competitive edge. The market is characterized by the presence of both global and regional players, offering a wide range of coil coating solutions.

Key Takeaways:

The global coil coatings market is expected to witness high growth, exhibiting a CAGR of 4.3% over the forecast period. The increasing construction activities, particularly in emerging economies, are driving market growth. For example, rapid urbanization and infrastructure development in countries like China and India are creating a significant demand for coil coatings.

In terms of regional analysis, Asia Pacific is expected to be the fastest-growing and dominating region in the coil coatings market. The region’s booming construction industry, increasing industrialization, and automotive production are fueling the demand for coil coatings. Moreover, favorable government initiatives to promote sustainable construction practices are further propelling market growth in this region.

Key players operating in the global coil coatings market include BASF SE, Henkel AG & Company, DuPont, The Beckers Group, Kansai Paint Chemical Limited, AkzoNobel, PPG Industries Inc., The Sherwin-Williams Company, and Wacker Chemie AG. These players are focusing on product development, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their customer base.

In conclusion, the global coil coatings market is poised for significant growth due to increasing construction activities and the demand for sustainable and energy-efficient buildings. The adoption of eco-friendly coil coating technologies and the dominance of the Asia Pacific region are key trends driving market growth. However, the market faces challenges from substitute coating technologies and intense competitive rivalry.